Get more freight out the door, faster

Improving how quickly freight flows through a facility usually means adding more people or equipment. But the Vaux Freight Movement System™ allows you to do more with what you already have. This material handling system is designed to speed up every step of loading and unloading freight, helping you turn trailers faster, reduce touches and keep product flowing.

How the Freight Movement System works

At the core of the Vaux Freight Movement System are our Vaux MP™ and MP Coupler™, which enable freight handling operators to rapidly load and unload trailers.

Let’s break down how freight moves through each part of the process.

Inside the trailer

The Vaux MP is designed to fit inside standard trailers and can be configured in thousands of ways to match your freight profile. Once loaded, the entire MP can be moved in and out in one smooth movement using a standard forklift equipped with the MP Coupler. That means no more handling pallets or pieces one by one.

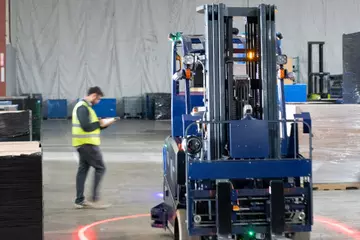

Outside of the trailer

Once outside, the system becomes even more flexible. The MP Coupler’s tight turning radius lets operators easily reposition the MP around the warehouse or dock. Freight-handling operators have access to all four sides of the MP, allowing them to pull product in seconds and entirely unload in minutes. We call this swarm processing, and it creates remarkable efficiency gains.

Compare to manual loading and unloading

Manual freight handling, whether by hand or forklift, remains the standard in many operations. But it comes with some well-known challenges:

It’s labor-Intensive. Manual processes require multiple dock workers, increasing labor costs and potential for injuries.

Timing can be inconsistent. Depending on the skill level of the team or the available equipment, the amount of time it takes to get freight on and off trailers can vary.

It requires multiple freight touches. If a piece of freight at the front of a trailer needs to be moved, every piece has to come off the trailer and be put back on. More handling often means more opportunities for freight to be mishandled or damaged.

The Vaux Freight Movement System was designed to address these pain points. Here’s how it compares:

| Factor | Manual Loading/Unloading | Vaux Freight Movement System |

|---|---|---|

| Speed | 45+ minutes per trailer | Less than 5 minutes per trailer |

| Safety | Higher risk of injury | Safer, controlled movement |

| Freight Handling | Multiple touches per shipment | Significantly reduced |

| Dock Efficiency | Limited throughput | High trailer turnover & reduced congestion |

On average, the Vaux system provides a 90% reduction in load and unload labor costs and a 50% reduction in damage costs when compared to traditional methods.

Interested in learning more?

With Vaux, companies have significant opportunities to enhance the efficiency and safety of their operations. Get in touch with our team to find out if Vaux is right for you.