Is your data center equipment being shipped the right way?

Shipping data center equipment is complex, and the rapid growth of facilities worldwide has only intensified the stakes. With increasing pressure to move and install hardware quickly and efficiently, companies are looking for ways to streamline operations. Traditional deployment methods can quickly create bottlenecks, slowing down installations and risking downtime.

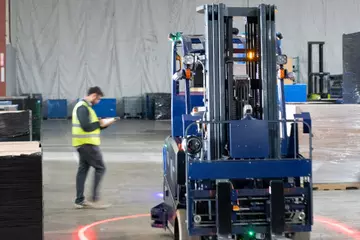

The Vaux Freight Movement System is changing that, enabling teams to safely handle heavy racks, reduce transportation costs and optimize operations in any data center environment.

Industry context: what’s fueling the growth?

Every online purchase, video call, AI query and streaming session relies on data centers. As companies modernize their IT systems and rely more on digital platforms, demand for scalable, reliable infrastructure has exploded. And there’s no sign of it slowing down.

This wave of construction is reshaping more than digital infrastructure. It’s transforming how materials and equipment move through the supply chain. Building and upgrading these facilities means transporting large, high-value components, often under tight timelines. Each project requires precise coordination and specialized handling to keep schedules on track and protect sensitive technology.

As data centers continue to scale, questions are emerging about how to move this material safely, efficiently and sustainably.

Challenges of shipping data center equipment

Data center equipment has several unique characteristics that make it challenging to ship:

Large, heavy parts.Racks and equipment are oversized and heavy, making moves in and out of data centers complex and labor-intensive.

Fragile components. Sensitive electronics can be damaged by vibration or shock during transit, putting critical systems at risk.

Limited loading options. Equipment often cannot be stacked like standard freight, which drives up handling complexity and cost.

Safety concerns. Handling heavy equipment without proper procedures or equipment exposes teams to injury and workplace hazards.

Sustainability questions. With data centers under scrutiny for their energy use, many companies are looking closely at the environmental impact of the supply chain that supports them.

How the Vaux Freight Movement System helps

Moving data center equipment is faster, safer and more cost-effective with the Vaux Freight Movement System. Engineered for efficiency and safety, it allows operators to move multiple racks at once through double or triple stacking. Fewer trips mean faster installations, lower transportation costs and a smaller environmental footprint.

The Freight Movement System is also built to adapt to the unique demands of your data center. The mobile platform has been tested in the lab and on the road to ensure equipment arrives safely. Vaux engineers can collaborate with your team to validate your racks or specialized use cases, creating a seamless fit for your environment.

Ready to transform how you ship servers?

The Vaux Freight Movement System gives your team the tools to move heavy racks safely, efficiently and cost-effectively — reducing labor, requiring fewer shipments and protecting valuable equipment every step of the way.

Whether you’re upgrading existing infrastructure or building a new facility, Vaux can help you complete projects faster, minimize risk and keep operations running smoothly.