Using autonomous mobile robots (AMRs) to transport materials

Efficiency, accuracy and productivity are the foundations of successful material-handling processes. In efforts to achieve them, the role of technology has become increasingly important, and one innovation stands out: autonomous mobile robots.

These agile and intelligent machines are not only optimizing material handling workflows but also unlocking new levels of flexibility and scalability.

Technology overview

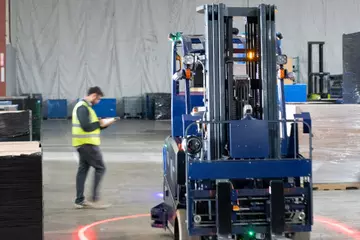

An autonomous mobile robot (AMR) is a robotic system that can navigate an environment without being directly operated by a person or restricted to a specific route.

AMRs use sensors, cameras and intelligent navigation systems to evaluate their surroundings and make real-time route decisions. This allows them to adapt to changes — making them well-suited for warehouse, dock and distribution environments where layouts may change frequently.

Rapid advancements make adoption easier than ever

While the concept of autonomous robots has been around for decades, advancements in sensor technology, navigation systems and artificial intelligence paved the way for practical applications of AMRs in the early to mid-2000s.

In the time since, many advancements have been made to improve performance and safety, helping them surpass previously used material-handling solutions in many applications. And innovation continues to take place. Recently, ArcBest announced a collaboration with NVIDIA that will bring cutting-edge machine vision technology to its AMR forklifts and reach trucks.

Learn about ArcBest’s Vaux Smart Autonomy offering

How AMRs compare to other material-handling technologies

When compared to other options, AMRs offer several advantages, including reduced costs, better working conditions and more versatility.

AMR vs AGV

While AMRs can navigate freely by evaluating their environment in real-time, Automated Guided Vehicles (AGVs) use magnetic strips or wires to move around a facility. Due to this fixed infrastructure, AGVs are designed for predictable, repetitive tasks in environments that won’t change.

AMRs vs conveyors

Conveyors are stationary systems designed for moving goods along predetermined paths. These systems are great for quickly moving large quantities of items in assembly lines or sorting centers, but they’re limited in where they can be placed and aren’t ideal for dynamic environments. This contrasts with the capability AMRs have to move freely and adapt to their locations.

AMR vs shuttle systems

Warehouse shuttles are a storage and retrieval system (AS/RS) that uses robots to transport products along fixed tracks. In these systems, goods are stored in racking structures with multiple levels, and the robotic shuttles move horizontally and vertically within these structures to retrieve and deposit items.

They work well in warehouses with high-volume storage and retrieval needs but aren’t suited for tasks or environments that need flexibility. If you’re looking for a dynamic solution, AMRs offer the flexibility you need.

Learn about the specific benefits of Vaux Smart Autonomy.

Industry applications

AMRs can revolutionize material handling processes for almost any industry but are frequently utilized in those with frequent material movement, dynamic environments and complex supply chains. These include:

- Automotive. Help with inventory management, material replenishment and facilitating just-in-time manufacturing processes.

- Manufacturing. Assist in transporting raw materials, delivering tools and parts to production operators, and moving finished products to staging areas for inspections, packaging or shipping.

- Retail. Used to streamline order picking and perform inventory audits, cycle counts and stock replenishment tasks.

- Food and Beverage. Can move pallets of products around warehouses, scan barcodes or RFID tags to update inventory systems, and transport ingredients to mixing stations.

Improve your processes with Vaux Smart Autonomy

In warehouse operations, staying competitive and profitable means embracing innovation. If AMRs seem like a good fit for your business, Vaux Smart Autonomy may be the solution you need. By integrating AMR forklifts and reach trucks with intelligent software and remote teleoperation features, Vaux streamlines critical supply chain processes.

Estimate the potential ROI of Vaux or connect with our team to find out how it can help optimize your workflows.